Key Supply Chain Metrics for Beef

The supply chain is the backbone of any modern business: an ever-shifting ecosystem that ensures the polish, efficient, and consistent commitment of products or services from a supplier to a client or customer.

If your supply concatenation lacks structure, vision, and efficiency or is fragmented, your commercial growth will suffer. That's why it'south critical to monitor and optimize relevant supply chain metrics and KPIs with pinpoint accuracy.

Supply chain metrics volition help you set solid benchmarks for a number of essential processes and activities. And by working with the right KPIs, you stand to make your business organization more productive, more than intelligent, and ultimately, more profitable.

In this post, we will cover essential supply chain KPIs and deliver essential insights about the twenty that you should track for improved logistics processes. Nosotros will as well show y'all how to maximize the value of these supply chain performance metrics with the help of modern KPI software to create professional person supply concatenation dashboards.

But commencement, let's start with the basic definition.

What Are Supply Chain Metrics?

Supply chain metrics are divers by establishing specific parameters which are used in quantifying and defining supply chain performance. The metrics tin can exist utilized in the inventory accuracy and turnover metrics, to the inventory-to-sales ratio.

Concerning the continual growth, development, development, and success of your company's supply, fulfillment, and delivery efforts, supply chain performance metrics are the most invaluable tools available at your fingertips. By collecting, curating, and analyzing central supply chain metrics (SCM) you will be able to spot inefficiencies within your ecosystem while capitalizing on your current strengths and establish goals that will help your supply chain calibration with the success of your visitor. While there are numerous KPI examples you can select for your assessment and optimization, nosotros have focused on a list that volition enable you lot to identify potential bottlenecks and ensure sustainable development.

Our Top 20 Supply Concatenation Metrics Examples

Call back: Today, having access to your metrics 24/7/365 is vital. Cutting-edge online data analysis tools will requite you this level of untapped data-driven access, increasing your commercial prospects in the process.

Now that you're familiar with the official supply chain metrics definition, we're going to explore the tiptop xx supply concatenation metrics that will assist you, and your business organisation, work toward a brilliant and prosperous future.

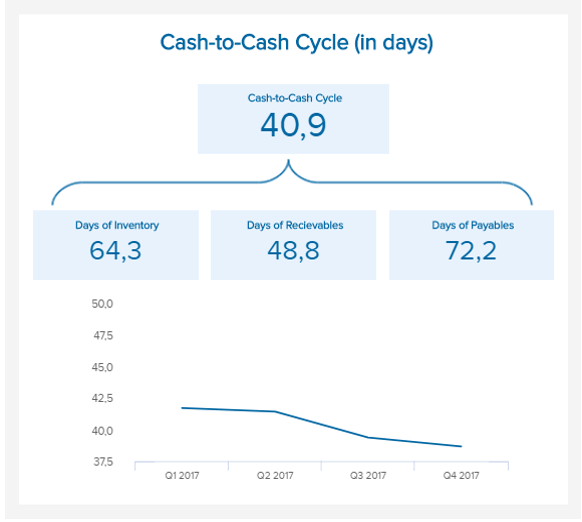

1. Greenbacks-to-cash Time Cycle

This priceless supply concatenation metric will help you calculate the length of fourth dimension required to transform your resources into bonafide cash flows. Working with iii core ratios - the days of inventory (DOI), the days of payables (DOP), and the days of receivables (DOR) - the cash-to-greenbacks time cycle KPI visualizes the menstruum required between the moment a business pays cash to its suppliers and the moment it receives cash from its customers. The shorter the conversion wheel the meliorate, and this invaluable supply chain metric volition help you take the correct measures to ensure that you can run your business with less coin tied up in operations.

two. Freight Beak Accurateness

Shipping and freighting your items from supplier to warehouse or warehouse to the consumer is vital to the success of your entire operation, and whatsoever consequence or error can prove harmful with time and investments beingness wasted.

Billing accuracy is critical to profitability as well as client satisfaction, so tracking this particular metric will assistance you lot spot detrimental trends, improve your overall aircraft accurateness, and ultimately, help your business grow. Hither is how freight bill accuracy is calculated:

(error-free freight bills / total freight bills) * 100

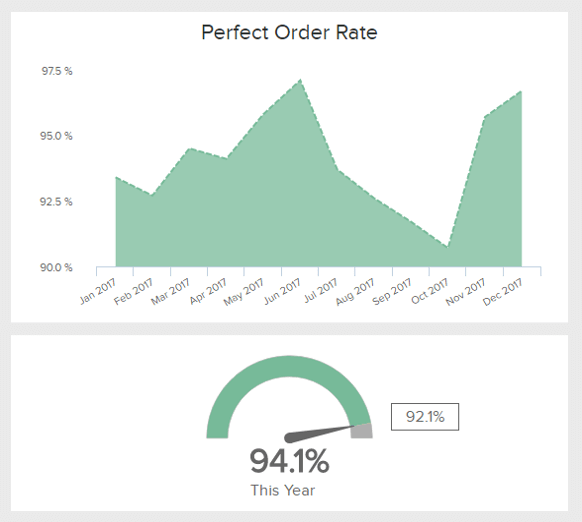

3. Perfect Order Rate

This particular insight is one of the most critical supply concatenation KPIs for businesses operating in a multitude of sectors. The perfect gild rate measures the success of your ability to evangelize orders incident-complimentary, which volition ultimately help you lot iron out bug such equally inaccuracies, damages, delays, and inventory losses. The higher the perfect order rate, the improve, considering this KPI has a direct impact on your client retention and loyalty levels.

4. Days Sales Outstanding (DSO)

The days sales outstanding (DSO) KPI measures how swiftly you are able to collect or generate revenue from your customers.

Essentially, a low, or healthy, DSO number means that it takes a business organization fewer days to collect its accounts receivable. A higher DSO level demonstrates that a company is selling its product to customers on credit and taking longer to collect revenue in a tangible sense, which can stunt greenbacks flow and minimize profits in the grand scheme of things. By computing this often, you lot'll be able to collect revenue faster and more efficiently, which volition help heave your lesser line in the long run.

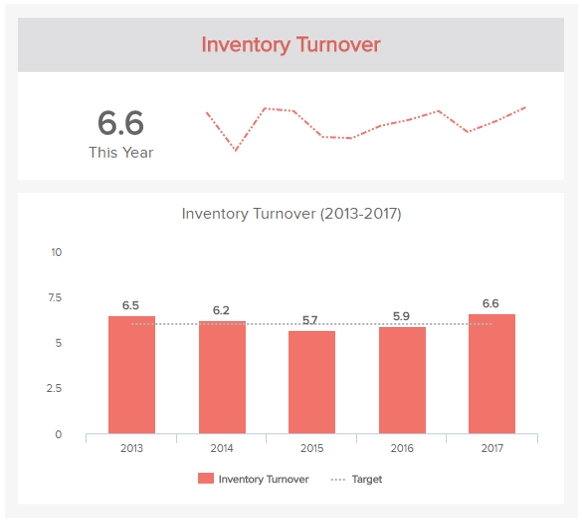

5. Inventory Turnover

One of the near superbly helpful supply concatenation KPI bachelor today focuses on logistics KPIs and helps a business organisation sympathise the number of times its entire inventory has been sold over a certain time frame: an incredible indicator of efficient production planning, process strategy, fulfillment abilities, and marketing and sales management. By calculating your on-fourth dimension aircraft rate and comparison it to other competitors within your industry, yous will be able to create a clear management reporting practise, come across where you stand up, and accept the advisable action to ameliorate it over time - this will effect in a boost in brand authorization likewise as an increased bottom line - so it's of import.

half-dozen. Gross Margin Render On Investment (GMROI)

Every concern, regardless of service, production, or sector strives to accomplish the best return on investment (ROI) for each and every commercial activeness it undertakes. Maintaining a consistently solid ROI is the staff of life and butter of ongoing eCommerce success.

In supply chain metrics, the GMROI offers a clear representation of the gross turn a profit gained for every AED (or $, £, €, ₺) of the average investment made in your inventory: a calculation accomplished by dividing the gross profit by the boilerplate inventory investment. By tracking this KPI on a monthly footing, yous'll quickly gain an insight into which items in your inventory are poor performers and which are worth investing in more - gold grit in terms of business-based information.

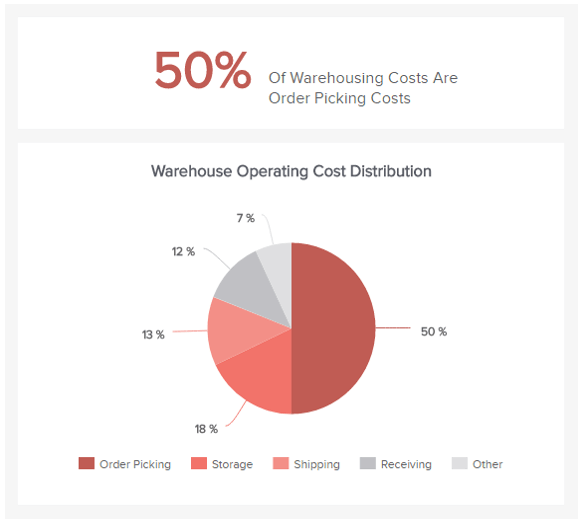

7. Warehousing Costs

We continue our list of supply chain metrics (SCM metrics) with the warehousing costs. The price distribution and the direction of the time and infinite of your inventory are critical in establishing a good for you supply chain. While such costs vary from warehouse to warehouse, information technology'south of import to measure this indicator and review it regularly in order to identify opportunities and decrease unwanted costs. The management of the warehouse facility includes various costs such every bit labor costs, warehouse rent, utility bills, equipment costs, textile, and information-handling systems likewise every bit costs related to supplies, ordering, and storing the goods.

Keeping the costs on the lower side of the spectrum starts with being well informed about all the processes that are happening at the warehouse facility and how exactly information technology operates. That style, y'all volition have a better chance to reduce unnecessary costs and introduce steps to manage operations more efficiently also as adjust them when needed. Likewise, if you collect your data on a regular footing with the aid of a professional online reporting tool, y'all will accept the opportunity to rely upon your reports and make faster, more than accurate business decisions.

8. Supply Concatenation Costs

Costs are i of the supply chain key performance indicators that shows relevant costs that are associated with supply chain management. These costs can include planning, managing teams, sourcing, delivering, etc., and it will show how efficient parts of the visitor are. It's critical for whatsoever business to increase its profit and reducing costs is one of the strategies that is often applied. That way, the company can identify if at that place is whatsoever space for improvement without the need to increase sales in the procedure.

However, it'south essential to evaluate what kind of impact the cost reduction volition accept on the whole supply chain. For example, if your transportation costs are high and you decide to push button the speed and weight of trucks, yous can hazard accidents and potentially detrimental consequences for your business. Yous may also continue in mind that cutting costs in ane area of the supply concatenation can increment in another so careful analysis in this part is essential. You can perform a criterion or compare yourself with competitors in order to know whether this KPI in supply concatenation is steady and salubrious or y'all need additional adjustments to be competitive. If yous want to learn more about costs and the financial side of the concern, we propose you lot read our guide on financial graphs.

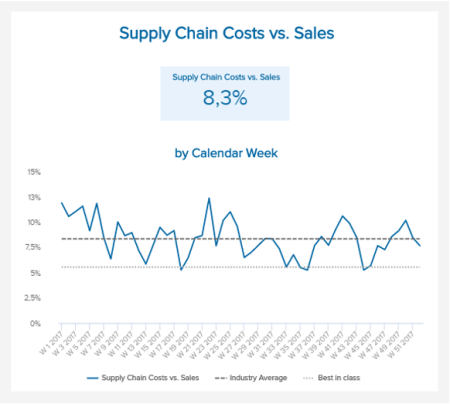

9. Supply Chain Costs vs. Sales

Our list of supply chain KPIs and metrics continues with additional cost analysis, connected to sales. This indicator basically calculates your supply concatenation costs every bit a portion of sales and, in essence, information technology will give y'all an indication of how much you are spending relative to a whole. By calculating such supply concatenation management metrics, you will be able to perform a healthy spend analysis and institute processes for potential savings. Optimizing the supply chain means reducing costs as much every bit possible but here, equally nosotros mentioned, information technology's of import to cut costs where it makes sense, and non only do it to bring down the numbers. The reason is simple: if you cut costs that are consequently increased in another part of your supply chain, the whole process is not very useful.

To know whether you lot're successful in comparing your costs with sales, you can simply research industry benchmarks or compare your business with competitors. That way, you will know whether your percentage is too depression or too high. In whatsoever case, information technology's critical to compare your data with the averages of the relevant industry.

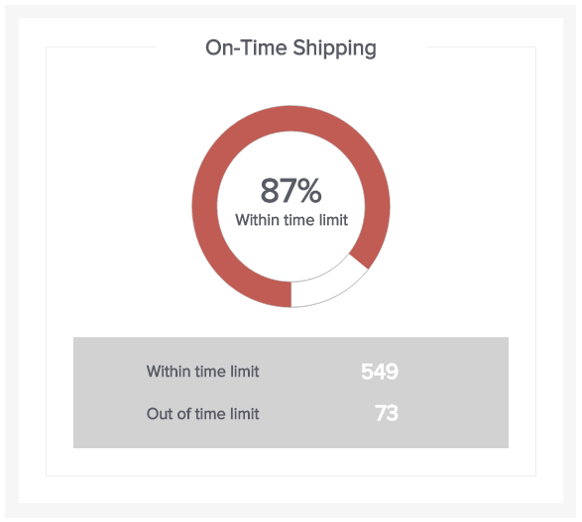

10. On-time Shipping

Created with a professional KPI tool, the on-time shipping is an excellent indicator of how long you may need to ship a detail type of society to a client, customer, or partner, this KPI volition allow you to ready a benchmark shipping fourth dimension relative to each product which, in turn, volition allow you to optimize your aircraft and delivery processes, reducing turnover time, and boosting client satisfaction levels.

11. Delivery Time

Delivery time is a KPI for supply concatenation that focuses on improving service: it measures the amount of time needed from the moment the gild is shipped to the delivery on the customers' doorstep. The order needs to be correctly prepared and the destination reached inside a reasonable time frame. Otherwise, the general service may exist affected and the impression you leave on your customers: no one likes to await for 9 months to get their delivered goods.

It makes sense to reduce this supply concatenation management KPI and create more precision in informing clients when the goods or products volition be delivered. It's much better to state that the commitment will arrive in iv-5 business days in comparison to i-5 business days. Moreover, if you lot manage to specify the time, even better for your service. You can as well offer special delivery services to subtract the delivery fourth dimension and see how your customer satisfaction, in the long run, rises. You can even include supply delivery metrics in your performance dashboard focused on the supply chain, and monitor it more closely. Please, meet the lesser of this article to take a closer look at a supply chain KPI dashboard.

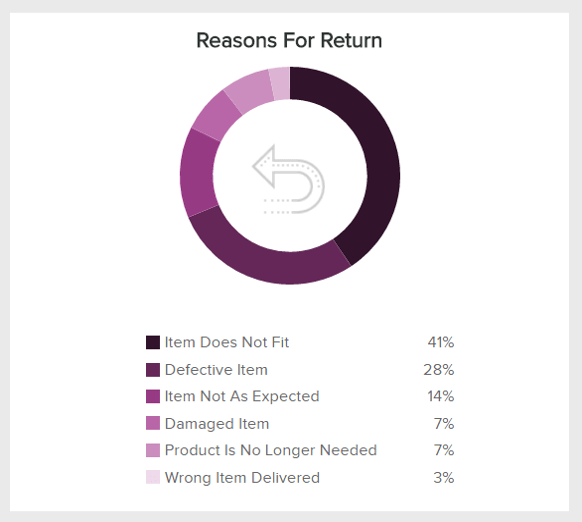

12. Return Reason

The return reason supply concatenation metric offers an astute insight into the various motives causing your customers and clients to render their orders – a piece of data that is priceless to the ongoing success of an eCommerce business. Presented in a digestible pie chart-style format with a key showcasing the primary reasons for return, you volition be able to assess your areas of weakness, clarify the quality of critical areas of your supply concatenation process, and make the kind of improvements that will enhance not only your reputation but your overall level of service significantly. By gaining this level of insight, you lot stand an excellent chance at decreasing returns, boosting profits, and improving greenbacks flow as a result.

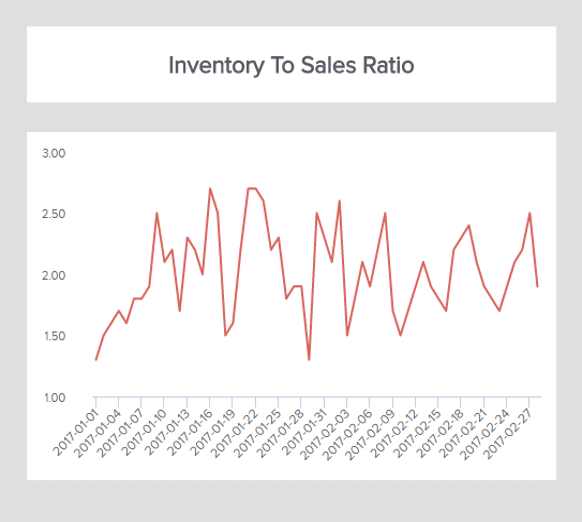

13. Inventory To Sales Ratio

One of the key supply chain metrics on our list, the inventory to sales ratio, is critical to track since inventory is one of the most of import instruments in your supply chain. This metric measures the amount of inventory for sale in comparison to the actual quantity that is sold, expressed every bit a ratio. Information technology will help y'all to adjust your stock in order to ensure high margins and tell y'all how well your company is dealing with unexpected situations.

Here the primary signal is that to continue a healthy ratio, you lot demand to know how to balance information technology properly. It would make sense to keep the ratio non besides high since it could touch on your inventory turnover rates and then the balancing act is essential. A modern dashboard maker tin can help you in creating an interactive inventory KPI that will update the data automatically and you can monitor the performance in real-time. Moreover, you will be able to accommodate your time to come strategies and ensure there is an optimal ratio, specific to your concern.

xiv. Inventory Velocity (IV)

A pivotal supply chain KPI, the inventory velocity, or Iv, provides a visual snapshot of the percentage of inventory that's projected for consumption inside the next period or quarter.

Calculated by dividing the opening stock by the sales forecast for the post-obit period, the IV is a KPI that will help yous optimize your inventory levels, give you lot a greater chance of meeting consumer demand, and prevent you from wasting coin on backlog levels of stock.

15. Inventory Days Of Supply

While this may non be the most panoramic or extensive of supply concatenation metrics, inventory days of supply is particularly useful as it will give yous a fairly authentic adding of the number of days it would have you to run out of stock if it wasn't replenished.

By tracking, analyzing, and understanding this stream data on a regular ground, you lot will exist able to fix for, and avoid, whatever stock-based calamities in an emergency situation, saving your reputation and cash flow in the procedure.

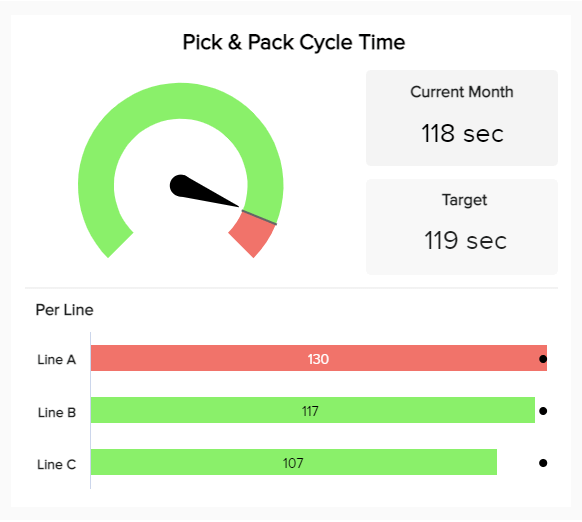

16. Option & pack cycle time

This supply chain performance measurement volition requite y'all an accurate gauge of simply how efficient (or inefficient) your unabridged supply chain wheel is, breaking it downwardly into specific lines. Each metric inside the KPI is designed to quantify the time from when an employee plucks an detail from the shelf to the moment the packing process is complete.

Once you've set your targets and started tracking your supply chain wheel progress, it will become clear where delays or weaknesses lie inside your supply chain. As a result, you can take targeted activity to nip these issues in the bud, driving down your overall cycle times in the process.

17. Fill rate

The adjacent on the list of supply chain management metrics is fill rate. An essential addition to whatever valuable supply chain KPI dashboard, this important metric will give you a articulate-cut indication of the proportion or percentage of your customers' orders that are successfully fulfilled the offset time effectually (or during the first shipment).

One of the about popular metrics used to mensurate supply chain performance, fill rate is directly linked to overall brand reputation and client satisfaction levels (meaning drivers of commercial growth and evolution). Y'all can benchmark your fill rates based on orders delivered, lines delivered, or individual items delivered on the showtime try. If you lot spot any discrepancies in your fill rate, you will be able to easily uncover the exact fulfillment factor and boost your make full rate swiftly.

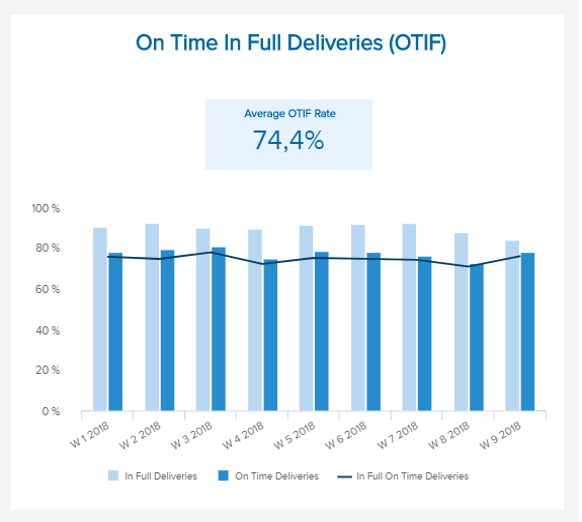

18. Delivered on time and in full (OTIF)

In terms of supply concatenation metrics that affair, OTIF is up there as this near powerful of supply chain KPI examples volition give you a panoramic insight of your commitment functioning over a set timeframe. Delivering on your clients' or customers' expectations is vital to the ongoing success of your business. Every bit one of the most insightful supply chain efficiency metrics, OTIF will ensure your orders are fulfilled in full and on time.

Based on factors such as whether the right product was delivered to the agreed quality standards, fulfilled in the right quantities, and delivered to the agreed destination, this KPI will help you consistently optimize your performance. If your boilerplate OTIF rates are lagging, you lot can employ this metric to pinpoint the factors at play and brand strategic decisions to tweak your internal strategy or piece of work with more than reliable suppliers.

19. Freight cost per unit of measurement

Metrics in supply chain management are critical for making sustainable improvements, and freight cost per unit is a testament to that notion. 1 of the most important supply concatenation metrics for any scaling business, freight toll per unit of measurement will provide you with a solid insight into how economically y'all can send your products.

This particular supply chain metrics dashboard add-on will measure your overall freight costs divided past the number of units you've shipped. You lot tin can calculate this metric using whatsoever unit of measurement that is relevant to your business organization. Any long-winded or poorly planned processes will cost you fourth dimension, money, and customer loyalty. This KPI will help you avoid such difficulties.

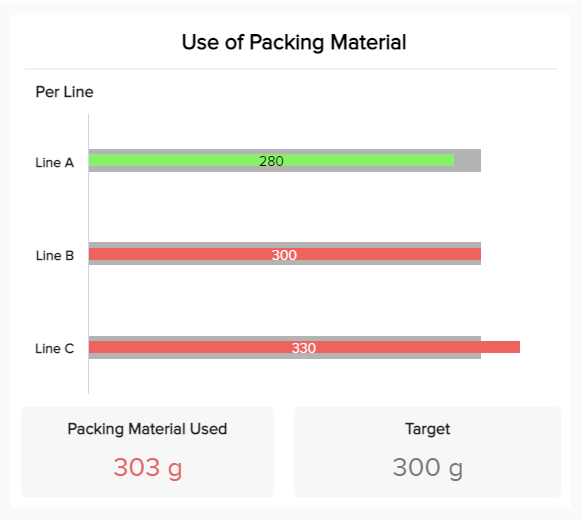

twenty. Utilise of packing material

The adjacent in our rundown of supply chain KPIs is the apply of packing materials. Not but do inefficient packing processes cause unnecessary waste, but they volition sap your business'southward upkeep. This scannable supply chain KPI will help you confidently track the amount of packing materials you lot're using for every line in your pick & pack process.

By setting a target or benchmark for your packing usage (in this example, it's 300g), you can stay on acme of your packaging usage and nip any potential bug in the bud. By reevaluating your packing strategies earlier they get out of hand, you will relieve money while boosting your brand reputation as a outcome of your newfound sustainability.

Supply Concatenation Management Dashboard Examples

Cheers to modern online data visualization tools you lot can create stunning supply chain management dashboards with all your needed KPIs with a few clicks. Every KPI in supply chain management works cohesively to pigment a bright picture that will propel your organization forward. These dashboard examples will demonstrate how:

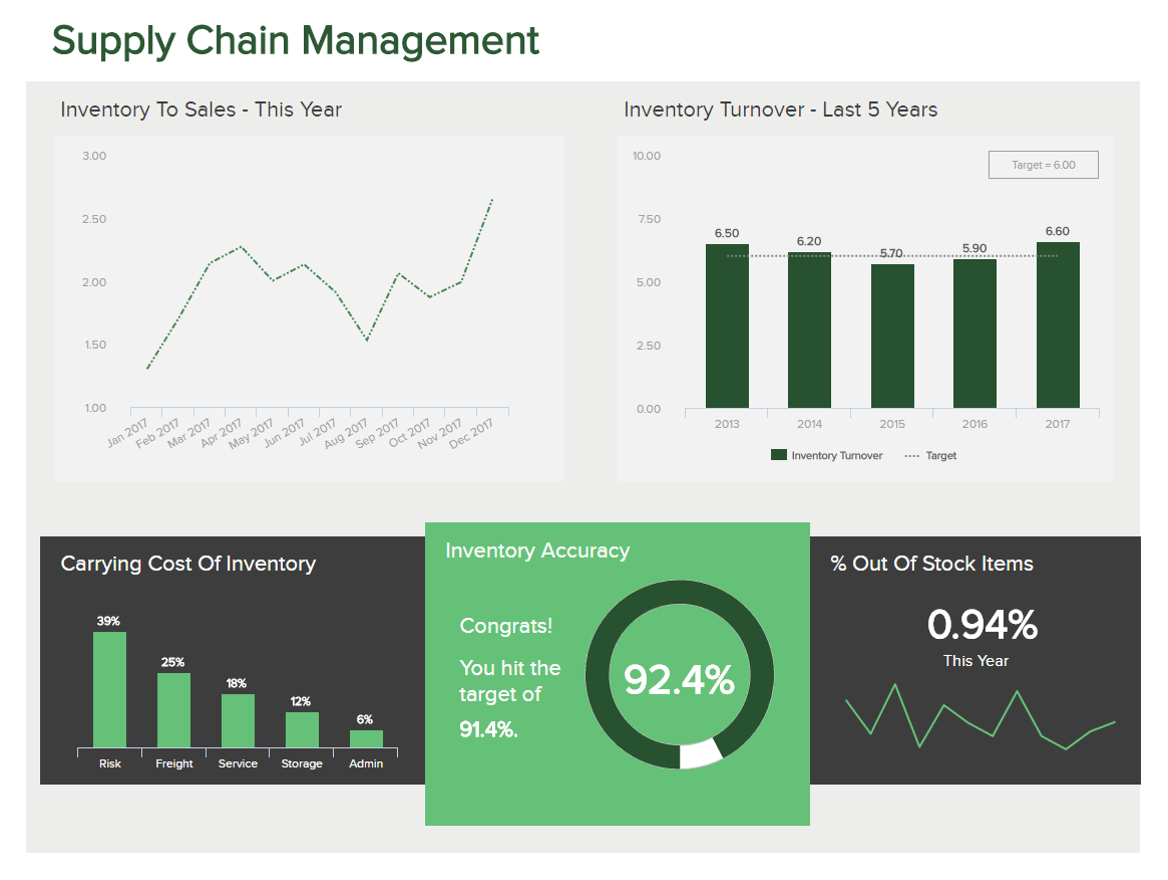

1. Supply Chain Management Dashboard

In the instance below, nosotros have collected data focusing on inventory metrics: Inventory-to-Sales ratio, which you can combine with the Inventory Turnover, and clearly see the financial stability of your business organisation. The next KPI of this detail dashboard is the carrying cost of inventory, followed by inventory accuracy and out-of-stock items. The goal in this instance is to avert wasting money, retain customers, and define the stability of a business.

**click to enlarge**

At that place'south no denying it: optimal supply concatenation management conducted in a continually consistent, strategic, and data-driven manner will yield incredibly fruitful long-term results - the kind that will help your business concern evolve and scale over time.

One of our most powerful business organization dashboards, the supply chain dashboard boasts a digestible, functional, and visual representation of all cardinal areas of supply chain performance, from inventory accurateness and turnover to the inventory-to-sales ratio. By drilling down into inventory direction logistics, this particular KPI dashboard (which tin can also be used equally an interactive dashboard) will assist you bargain with unexpected supply concatenation situations, enhance your stock ownership practices, reduce operational also equally financial inefficiencies, significantly meliorate the accurateness of your and a great bargain more. Your stock is essential to your commercial operation which is why tracking your inventory through a central nerve center will brand certain that every supply chain effort and initiative improves the way you run your business every bit opposed to hindering it.

Past tracking these critical supply chain performance metrics in i initiative space, you will exist able to implement initiatives that non only concord maximum value but will besides ensure the shine running and perpetual improvements of your supply concatenation processes, ensuring that every single cog in the wheel is turning to maximum efficiency - which of course, is priceless.

If y'all want to learn how to create a dashboard like this 1, check out our insightful guide with examples from different industries and functions.

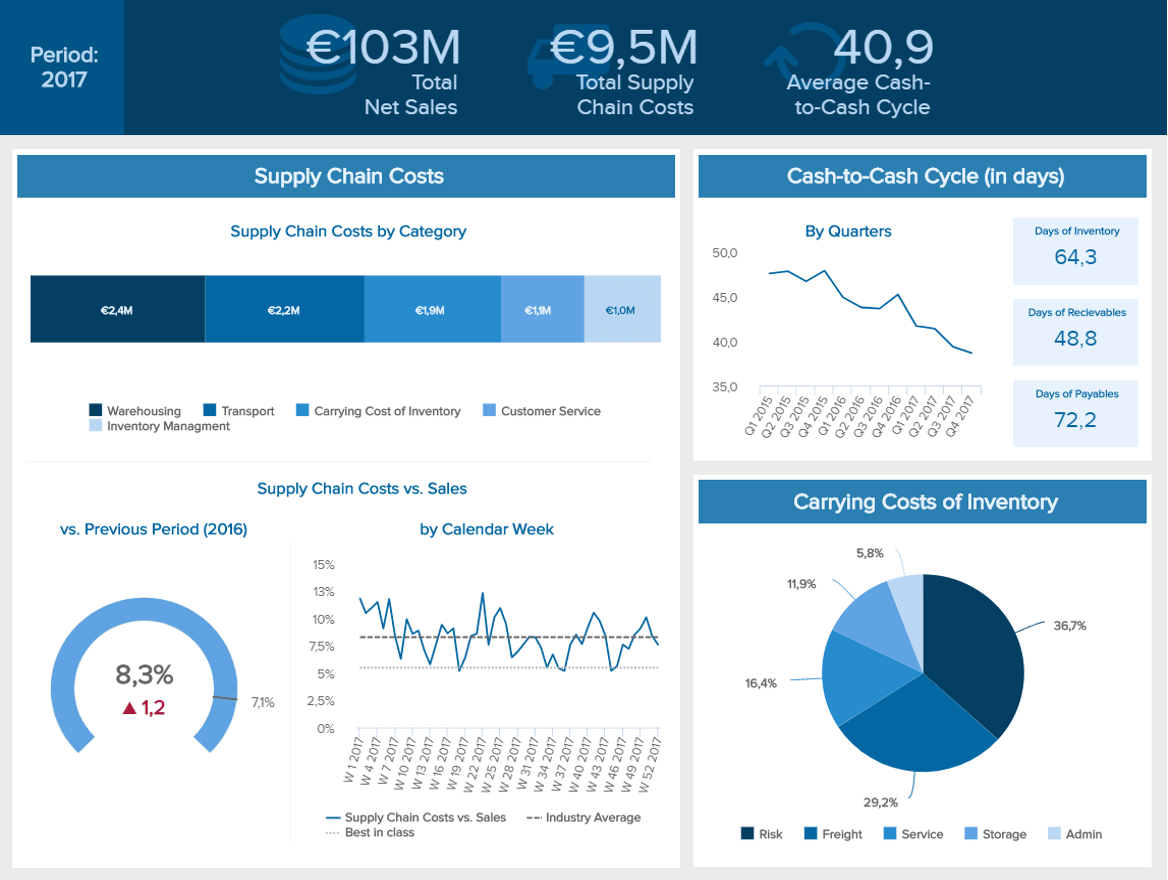

ii. Supply Chain Costs Dashboard

Consumer goods are another important manufacture that relies on effective supply chain direction. Peculiarly when information technology comes to cost optimization, there should be not much room for ignoring the financial analysis as it can cause serious damages to the bottom line. A comprehensive BI dashboard can help you in automating your KPIs and ensuring y'all focus on what really matters: the information, visuals, and data in front of you lot.

**click to overstate**

On elevation of this supply concatenation metrics dashboard, yous can run across a quick overview of the total cyberspace sales, total supply concatenation costs, and the average cash-to-cash cycle, all-important supply concatenation management metrics to start your data presentation. On the left side are represented supply concatenation costs by category that includes warehousing, transport, carrying costs of inventory, client service, and inventory management. Below these indicators, there is a clear overview of the supply chain costs vs sales. This KPI is additionally cleaved down by agenda week and compared to the previous menstruum. We have already analyzed this metric then we won't go into much detail but the important thing to keep in mind is to track this metric and perform a more detailed spend analysis and, finally, adjust if needed.

On the correct side of this supply concatenation performance dashboard are additional cost-related essential metrics: the cash-to-greenbacks cycle and conveying costs of inventory. These metrics are essential if you want to know how much cash you need to finance ongoing operations and how much turn a profit you can brand based on your inventory. Such an online dashboard you can easily create with a supply chain dashboard software.

Why Are Supply Concatenation Metrics Important?

Now that we've covered supply chain key performance indicators examples and the dashboards that bring them to life, nosotros're going to reflect past answering the question: Why are supply chain metrics of import?

Supply concatenation-based metrics are vital to your company's core fulfillment and logistics strategy for many reasons. In fact, studies say that the supply chain analytics market is expected to reach a value of $16.82 billion by 2027. This is due to the fact that using analytics for supply concatenation decision-making helps businesses better their operational, strategic, and tactical efficiency.

Hither are the primary benefits and reasons why KPI tracking is so important in supply chain management:

Communication & cohesion

The central to a successful supply chain is communication. One time everyone involved in the process has a deeper understanding of their office while gaining access to the metrics required to maximize their potential, every cog in the supply concatenation machine will become smoother, more economical, and more reliable.

KPIs and metrics like this provide unified admission to invaluable data - the kind that will meliorate advice, aid collaboration, and ensure your inventory is managed economically while every production travels from your warehouse to the end recipient without a hitch.

Focused data & supply chain insights

In the historic period of data, fulfillment processes can become overly complicated due to the ever-growing number of sources, platforms, and touchpoints to analyze. Wading through an ever-expanding pile of data apace becomes an uphill struggle when you're managing busy supply chains. Merely KPIs will give you the power to focus exclusively on the data that matters.

Supply chain-based metrics visualize what really counts from i centralized location in a visual format that is digestible. Working with supply chain-fashion metrics will assist you not merely run your logistical operations better but also place whatever rising issues (gaps in inventory, a lack of inventory, bottlenecks in your delivery processes, etc.) before they snowball or spot hidden trends that volition significantly improve your overall strategy.

Responsivity & adaptability

Supply concatenation KPI functioning indicators are disquisitional, as they will give y'all all of the insight you need to remain responsive and adaptable at all times. Successful supply concatenation management commands 100% adaptability in every situation. If something goes wrong (and when you're talking about supply chains with several stages to consider, something almost e'er will at some betoken), you must exist able to prepare it immediately.

As client demands go along to evolve, and the business mural keeps on shifting, ensuring your supply chain is robust will set you apart from the pack. Supply concatenation-focused metrics will give you the confidence and intelligence to brand valuable strategic changes to your processes based on the landscape effectually y'all while confidently making in-the-moment decisions thanks to target data visualizations you tin can analyze at a glance. The more than consistently you meet or exceed your client's or consumer'due south fulfillment expectations, the more than your business will grow - supply chain-based metrics will help you practise just that.

By beingness able to make projections that offer existent value and brand informed choices under force per unit area, you will optimize your supply concatenation for consistent success in a competitive commercial world. This, in turn, will maximize your growth and profitability.

Summary & Next Steps

Recent studies suggest that 79% of companies with high-performing supply chains earn a revenue growth greater than the boilerplate inside their sector. Moreover, the usage of the software is growing nine% year over yr, showing that this lucent value of developing an efficient supply concatenation lays within modern solutions to improve a company's functioning.

That'southward where the power of the dashboard comes into play. If you desire to create a data-driven visitor, save endless hours in the assay processes, and work with existent-time data, dashboards are a bang-up way to do so. And for more than data-driven wisdom, check out these great dashboard designs that you can get inspiration from.

And so, what are metrics in supply chain? Well, here is a summary of our acme 20 supply chain KPIs we discussed in item:

- Cash-to-greenbacks Time Bike

- Freight Bill Accuracy

- Perfect Club Rate

- Days Sales Outstanding (DSO)

- Inventory Turnover

- Gross Margin Return On Investment (GMROI)

- Warehousing Costs

- Supply Chain Costs

- Supply Chain Costs vs Sales

- On-fourth dimension Shipping

- Commitment Time

- Render Reason

- Inventory To Sales Ratio

- Inventory Velocity (Iv)

- Inventory days of supply

- Pick and pack wheel time

- Fill rate

- On-fourth dimension and in-full deliveries

- Freight cost per unit

- Use of packaging material

Each of these essential supply chain-centric KPIs will brand your organization stronger, smarter, and more than economically efficient from the ground up. By making your supply chain completely cohesive from commencement to finish, you will advance your concern'south growth in ways you lot never thought possible - and it all starts with the right insights.

If you want to track and visualize your supply chain metrics and KPIs with pinpoint accuracy and consummate convenience, you can endeavor our modern logistics analytics software for a free 14-day trial!

Source: https://www.datapine.com/blog/supply-chain-metrics-and-kpis/

0 Response to "Key Supply Chain Metrics for Beef"

Post a Comment